Iron Ore Engineers

Andrew Squire is an engineering superintendent who gives technical assistance to various FMGL departments such as oil processing and infrastructure. He possesses a mechanical engineering degree, and initially worked in a mine in North Qld but moved into iron ore because he feels that it is a good thing to have on his resume. Andrew has worked in coal and zinc, and enjoys FMGL because he is doing more technical engineering work than in his last role.

His typical day involves getting to work at 5am – checking emails, attending the pre-start meeting, co-ordinating people, fixing dramas, following up with project supplies, planning maintenance work on the machines. His work schedule varies, depending on if there is some disruption like a breakdown.

Technical staff support engineers in the project, take field measurements, drawings, documentation, help develop procedures and standards, liaise with suppliers/contractors.

Andrew currently manages nine people (trade qualified staff, as well as degree qualified employees), and is looking to increase his workforce to 23 staff, which he is hard-pressed to find (as he works 5:30am to 5:30pm in the workshop). Andrew seeks highly motivated people with good planning skills, technical ability and aptitude to challenge and modify designs. He believes that finding the right people will be the biggest hindrance to further FMGL development.

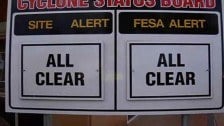

SkillsOne visited tradies who work in the mining industry in the Pilbarra, in Western Australia, run by Fortescue Metals Group.